Publicidad

Idiomas disponibles

Idiomas disponibles

Enlaces rápidos

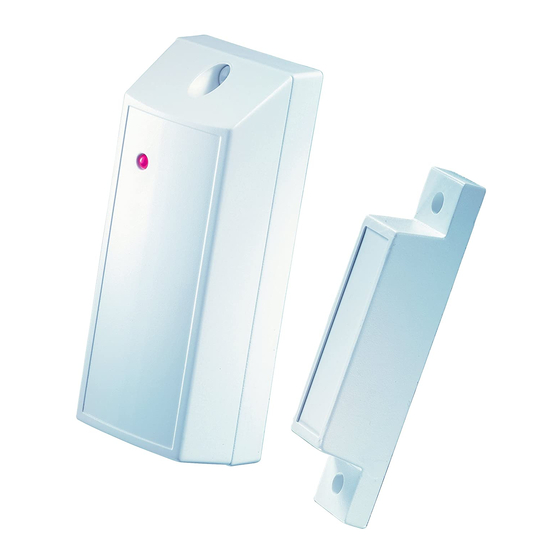

MCT-302

English

PowerCode Magnetic Contact Transmitter

Contacto Magnético Inalámbrico PowerCode

Español

ENGLISH

1. INTRODUCTION

The MCT-302 is a fully supervised, PowerCode magnetic contact

transmitter. For UL installations, the MCT-302 is for use with the UL

listed control unit, model PowerMax+ only. The transmitter includes

a built-in reed switch (that opens upon removal of a magnet placed

near it) and an auxiliary hard-wired input, programmable as either

N.C. or E.O.L., for use with additional sensors - pushbuttons,

detectors, door contacts etc.

An on-board DIP switch allows the installer to disable the

magnet- operated reed switch if only the auxiliary input is needed.

The reed switch and the auxiliary input behave as separate

transmitters, although they trigger the same RF transmitter. Each

input has a unique 24-bit PowerCode ID, selected in the factory

from over 16 million possible code combinations.

Since messages transmitted by the MCT-302 might collide with

transmissions from other PowerCode transmitters, a "smart" anti-

collision transmission sequence is used.

The MCT-302 tamper switch is activated when the cover is

removed.

A periodic supervision message, is transmitted automatically. The

target receiver is thus informed, at regular intervals, of the unit's

active participation in the system.

An LED lights whenever alarm or tamper events are reported.

The LED does not light while a supervision message is being

transmitted.

Operating power is obtained from an on-board 3 V Lithium

battery. When the battery voltage is low, a "low battery" message

is sent to the receiver.

2. SPECIFICATIONS

Frequency (MHz): 315, 433.92, 868.95, 869.2625 or according

to local requirements (UL has only investigated at 315 MHz).

Transmitter's ID Code: 24-bit digital word, over 16 million

combinations, pulse width modulation.

Overall Message Length: 36 bits

Alarm Inputs: 2, one internal and one external, with a separate

24-bit transmitter ID each.

Auxiliary Input Circuit Type: N.C. / E.O.L., selected with DIP

switch

E.O.L. Resistor Required: 47 kΩ

Message Repetition: Repetitive transmission (once every 3

minutes) or one-shot, as selected with on-board DIP switch.

Supervision: Signaling at 60-min. (USA) or 15 min. (Europe)

intervals, or according to local standards.

Response to Tamper Event: Tamper report every 3 minutes

(until the tamper switch is restored).

Power Source: 3 V Lithium CR-2 type battery, Panasonic or Sanyo

only.

Battery Life Expectancy: 3 years (for typical use)

Battery Supervision: Automatic transmission of battery condition

data as part of any status report.

Operating Temperature: 0°C to 49°C (32°F to 120°F).

Dimensions: 81 x 32 x 25 mm (3-3/16 x 1-1/4 x 1 in.)

Weight: 53g (1.9 oz)

D-300371

GB/US: TRANSMISSION LED

SP: LED DE TRANSMIÓN

Standards: Meets FCC Part 15, MPT1349 and Directive

1999/5/EC,

EN 50131-1, Grade 2, Class II.

This device complies with Part 15 of the FCC Rules and RSS-

210 of Industry and Science Canada. Operation is subject to the

following two conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any interference

received, including interference that may cause undesired

operation.

This device complies with the essential requirements and

provisions of Directive 1999/5/EC of the European Parliament

and of the Council of 9 March 1999 on radio and

telecommunications terminal equipment.

3. INSTALLATION

3.1 Mounting

(Fig. 2)

It is highly recommended to attach the transmitter to the top of the

door/window on the fixed frame and the magnet to the movable part

(door or window). Make sure that the magnet is located not more

than 6 mm (0.25 in.) from the transmitter's marked side.

Note: Once the cover is removed, a tamper message is

transmitted to the receiver. Subsequent removal of the battery

prevents transmission of "TAMPER RESTORE", leaving the

receiver in permanent alert. To avoid this, press the tamper

switch while you remove the battery.

3.2 Auxiliary Input Wiring

Remember! If your application does not require the auxiliary

input, be sure to set DIP switch SW2 to OFF and to short the

input terminals together with a piece of jumper wire.

A. Connect the auxiliary sensor contacts across the MCT-302

auxiliary input terminals.

B. If the auxiliary input of the MCT-302 is defined as a Normally

Closed (N.C.) type (SW2 set to OFF), series connected N.C.

sensor contacts must be used exclusively. An E.O.L. resistor

will not be required.

C. For E.O.L. supervision, set SW2 to ON.

Normally Closed (N.C.) as well as Normally Open (N.O.)

sensor contacts can be used, as show in figure 3. A 47kΩ

E.O.L. resistor must be wired at the far end of the zone loop.

Note: For UL installations, the device connected to the initiating

circuit must be located in the same room as the transmitter.

4. PREPARATION FOR USE

4.1 The Function Switches

A. Switch Tasks

The MCT-302 has a 4-position DIP switch function selector. Each

switch lever allows you to select one of two options.

B. Setting the Switches

Set the function switches as desired prior

to applying power. Use a ball point pen or

another pointed object to shift the switch

levers. The ON position is indicated by

the arrow on the switch body.

GB/US: MAGNET

SP: IMÁN

Fig. 1 - MCT-302

(Fig. 3)

ON

1

2

3

Function Selector

4

1

Publicidad

Resumen de contenidos para Visonic MCT-302

- Página 1 (UL has only investigated at 315 MHz). B. If the auxiliary input of the MCT-302 is defined as a Normally Transmitter's ID Code: 24-bit digital word, over 16 million Closed (N.C.) type (SW2 set to OFF), series connected N.C.

- Página 2 (if used) and the auxiliary input (if used). enable/disable Restore events not reported ATTENTION! Each input of the MCT-302 has a different ID. Transmit mode Alarms reported every 3 min. You must enroll the ID that you are using (if you are using the...

- Página 3 Normalmente Cerrada (N.C.) (SW2 en OFF), se deben utilizar PowerCode, se utiliza una secuencia anticolisión "inteligente" de exclusivamente los contactos del sensor N.C. conectado en transmisión. serie. No se necesitará una resistencia R.F.L. El tamper del MCT-302 se activa cuando se quita la tapa. mensaje supervisión periódico, transmite C.

- Página 4 Nota: Ya que la tapa se quita y se aplica alimentación, existe los más altos estándares. Sin embargo, debido a la baja potencia una situación de tamper. Verifique que el MCT-302 transmite de transmisión y cobertura limitada (requerido por FCC y otras (el LED luce brevemente) una vez cada 3 minutos.