Eaton CROUSE-HINDS Serie Información De Instalación Y Mantenimiento

Ocultar thumbs

Ver también para CROUSE-HINDS Serie:

- Información seguridad (28 páginas) ,

- Información de instalación y mantenimiento (16 páginas) ,

- Nformación de instalación y mantenimiento (15 páginas)

Tabla de contenido

Publicidad

Idiomas disponibles

Idiomas disponibles

Enlaces rápidos

EIC ATEX combination line starters

Installation & maintenance information

APPLICATION

EIC combination line starters are used for general motor control and circuit protection in

hazardous environments. They provide motor branch circuit protection, motor running

protection, under voltage protection and remote starting and stopping by means of a

combination of thermal magnetic circuit breakers and magnetic motor starters.

INSTALLATION

To avoid risk of electrical shock, electrical power must be OFF before and during

installation and maintenance.

1.

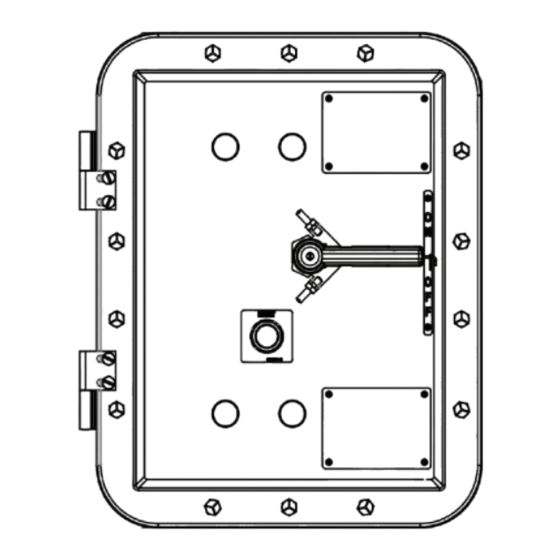

Select a mounting location that will provide suitable strength and rigidity for

supporting all contained wiring, components and control devices. Figure 1 and Table

1 show the mounting dimensions.

Inside nominal dimensions

EIC size

W

L

Size A

10 (254)

14 (356)

Size B

12 (305)

18 (457)

Size C

12 (305)

36 (914)

*Use M10 bolts for size A and M13 bolts for sizes B and C.

†External ground lug hole provided for all units. Hole is located on hinge side of body for sizes B and C.

A

B

2.

Securely fasten the enclosure to the mounting location, then attach into cable or

conduit system. Install approved conduit sealing fittings when required by the national

installation codes plus any other applicable standards.

To avoid risk of ignition:

•

Hazardous location information specifying class and group listing of each device

is marked on the nameplate of each enclosure. Class and group listing for any

device penetrating the enclosure must be suitable for the classification of the

location in which the enclosure is installed.

•

Unused entries must be plugged using suitably certified Ex d IIC Gb and Ex tb

IIIC Db blanking elements.

•

Entry to the enclosure must be made by suitably certified Ex d IIC Gb and Ex

tb IIIC Db cable gland or suitably certified conduit seal installed at the enclosure

wall.

•

For hazardous rated locations, all cable entries must be fitted with appropriately

rated cable glands as per local code requirements.

3.

Pull wires into enclosure, making sure they are long enough to make the required

connections. Make all electrical connections. The internal grounding terminals (lugs)

shall be used as equipment grounding means. The external ground terminal (lug) is

only a supplemental bonding connection.

4.

Test wiring for correctness with continuity checks and also for unwanted grounds with

insulation resistance tester.

To avoid risk of ignition:

Clean both ground joint surfaces of body and cover before closing. Dirt or foreign

material must not accumulate on flat ground joint surfaces. Surfaces must seat fully

against each other to provide a proper explosionproof seal.

5.

Close the cover, making sure that cover and body ground joint surfaces are clean with

no damage or scratches. Fully tighten all cover bolts to torque values per Table A2.

IF 1852 • 10/18

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

WARNING

Overall dimensions

Usable

D

depth

A

6 (152)

6.63 (168)

15.81 (402)

8 (203)

8.78 (223)

18.63 (473)

8 (203)

8.94 (227)

18.50 (470)

C

E

H

Figure 1

CAUTION

CAUTION

Copyright © 2018, Eaton's Crouse-Hinds Division

EIC enclosures should be installed, inspected and serviced by qualified and competent

personnel.

CERTIFICATIONS

IECEx:

•

Ex db IIB + H

Gb

2

•

Ex tb IIIC Db IP66

•

-20°C ≤ Ta ≤ +60°C

•

IECEx ETL 13.0022U

Mounting

B

C

E

19.13 (486)

10.50 (267)

9.00 (229)

23.31 (592)

12.81 (325)

15.25 (387)

41.25 (1048)

13.50 (343)

15.25 (387)

Table 1, in inches (millimeters)

Ø G

(4 PLACES)

To avoid nuisance tripping, ensure that EIC enclosure is mounted in a shaded

area, avoiding direct sunlight.

6.

Seal all wiring using appropriate glands.

F

To maintain environmental ratings, EIC enclosure shall be installed in the

horizontal position; vertical position (facing up) is not permitted.

BREATHER AND DRAIN

When used, check breather and/or drain to be certain that they are suitable for the

hazardous location, as well as for the environmental ratings in which they are being

installed.

For installation or removal of breather and/or drain, reference IF 843.

GROUNDING AND BONDING

Grounding and bonding of the conduit and equipment is required by the national installation

codes. A grounding conductor, when used, must be connected to the grounding lug(s),

furnished.

Determine the type of distribution system to be used that complies with national

requirements and ensures grounding continuity.

All conductive materials that enclose the electrical conductors, attached equipment or

forming part of such equipment, must be grounded. A permanent conducting connection

must be made between all such equipment and the earth.

INSTALLATION OF INTERNAL COMPONENTS

If an unpopulated EIC (without circuit breaker/HMCP or motor starter) is supplied, the

addition of components/devices is required. Also, the addition of components to the

internal operators for the circuit breaker/HMCP and motor starter must be installed. See

Table 2 for assembly details.

NOTE: The interior mounting plate may be removed to aid in the installation of the circuit

breaker/HMCP , motor starter and other optional equipment.

ATEX:

•

II 2 G D Ex db IIB + H

•

Ex tb IIIC Db IP66

•

-20°C ≤ Ta ≤ +60°C

•

ITS13ATEX17813U certified

F

G*

H†

17.13 (435)

0.43 (11)

1/4-20

11.50 (292)

0.56 (14)

5/16-18

29.50 (749)

0.56 (14)

5/16-18

CAUTION

CAUTION

IF 1852

Gb

2

Weight

Weight

(lbs.)

(kg.)

75

34

120

54

245

111

Page 1

Publicidad

Tabla de contenido

Resumen de contenidos para Eaton CROUSE-HINDS Serie

- Página 1 Close the cover, making sure that cover and body ground joint surfaces are clean with no damage or scratches. Fully tighten all cover bolts to torque values per Table A2. IF 1852 • 10/18 Copyright © 2018, Eaton’s Crouse-Hinds Division Page 1...

-

Página 2: Wiring Connections

Starter options options ground lug Terminal blocks Heater options Eaton MTE Eaton EG C0100E2A Eaton Space Savings AN13 NEMA size 0-2 Burndy KPA8C C0100E4C Eaton HMCPE with Eaton PFK1 fuse kit Buchanan terminal block Eaton MTE Eaton EG 1546234-1... - Página 3 Crouse-Hinds series EMPX operators are available for use with the EIC motor control series. EMPX operators can be installed before or after components are secured to the mounting plate. Consult Eaton’s Crouse-Hinds Division’s catalog for details. Reference IF 1857 for further information on EMPX operators.

- Página 4 All statements, technical information and recommendations contained herein are based on information and tests we believe to be reliable. The accuracy or completeness thereof are not guaranteed. In accordance with Eaton’s Crouse-Hinds Division’s “Terms and Conditions of Sale,” and since conditions of use are outside our control, the purchaser should determine the suitability of the product for his intended use and assumes all risk and liability whatsoever in connection therewith.

-

Página 5: Arrancadores De Línea De Combinación Eic Atex

Ajuste completamente todos los pernos de la cubierta a los valores de torsión como se indica en el Cuadro A2. IF 1852 • 10/18 Copyright © 2018, División de Crouse-Hinds de Eaton Página 1... -

Página 6: Instalación Del Disyuntor De Circuito/Hmcp

EJE DE AJUSTE reinicie el arrancador. Accione manualmente del disyuntor (los disyuntores de la serie G de Eaton vienen con soporte físico para el el arrancador y verifique que el operador de montaje). -

Página 7: Instalación Del Operador Empx

EIC. Los operadores EMPX se pueden instalar antes o después de que los componentes estén asegurados en la placa de montaje. Consulte el catálogo de la División Crouse-Hinds de Eaton para más obtener detalles. Consulte IF 1857 para obtener más información sobre los operadores de EMPX. - Página 8 Todas las declaraciones, la información técnica y las recomendaciones contenidas en este documento se basan en informaciones y pruebas que consideramos confiables. No se garantiza que las mismas sean precisas o estén completas. En conformidad con los ”Términos y condiciones de venta“ de la División Crouse-Hinds de Eaton y dado que las condiciones de uso están fuera de nuestro control, el comprador debe determinar la idoneidad del producto para su uso previsto y asume todo riesgo y responsabilidad con relación al mismo.

- Página 9 La poussière ou des matières étrangères ne doivent pas s’accumuler sur les composants optionnels. surfaces de joint plat. Les surfaces doivent être entièrement collées l’une sur l’autre pour fournir un joint antidéflagrant approprié. IF 1852 • 10/18 © Eaton’s Crouse-Hinds Division, 2018 Page 1...

- Página 10 à la plaque de montage à l’aide des vis du démarreur. Une fois la hauteur réglée, fournies par le fabricant du disjoncteur (les disjoncteurs de série G d’Eaton viennent serrer le contre-écrou au couple de 30 lb-po (4,5 Nm). avec la quincaillerie de montage).

-

Página 11: Raccordements Électriques

EIC. Les actionneurs EMPX peuvent être installés avant ou après la fixation des composants à la plaque de montage. Consulter le catalogue d’Eaton’s Crouse-Hinds Division pour les détails. Se reporter au document IF 1857 pour obtenir des renseignements supplémentaires sur les actionneurs EMPX. - Página 12 Toutes les déclarations, les recommandations et les informations techniques contenues dans le présent document sont basées sur des informations et des essais que nous croyons fiables. Leur exactitude ou leur exhaustivité ne sont pas garanties. Conformément aux conditions de vente d’Eaton’s Crouse-Hinds Division, et étant donné que les conditions d’utilisation sont hors de notre contrôle, l’acheteur doit déterminer si le produit convient à...