Resumen de contenidos para Atlanta Attachment Company 211ES

- Página 1 211ES Model Revision 1 Updated Dec 3, 2012 Technical Manual & Parts Lists Atlanta Attachment Company 362 Industrial Park Drive Lawrenceville, GA 30046 770-963-7369 • www.atlatt.com...

-

Página 3: Dobladillador

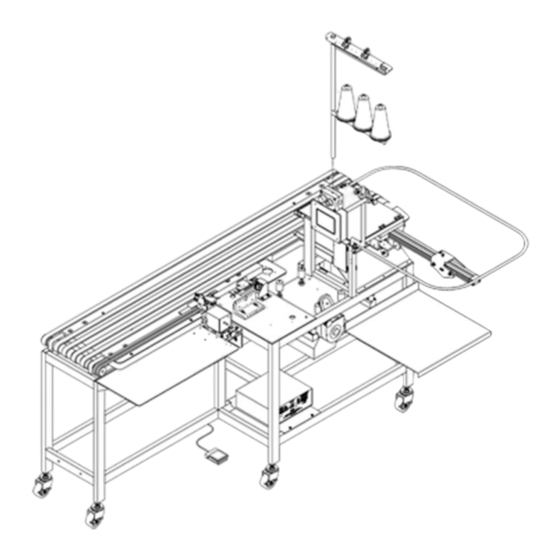

Technical Manual & Parts Lists Manual No. ZZ211ES Manual No. ZZ211ES Automatic Dobladillador Two Needle Hemmer Automatico De 2 Agujas Installation Intructions, Instrucciones de Instalación, Parts Lists Lista De Partes, And Diagrams For y Diagramas Para 2211ES 2211ES Automatic Dobladillador Two Needle Hemmer Automático de Dos Agujas. -

Página 4: Tabla De Contenido

Technical Manual & Parts Lists Contents Operating Instructions ..................................3 Instrucciones de Operación................................. 3 Control Box ........................................ 4 Instructions for 211ES ..................................4 Instrucciones para la 211ES................................4 211ES Main Screen: ....................................5 Advanced Functions: ....................................5 Primera Página de la Pantalla ................................5 Funciones Técnicas .................................... - Página 5 025-001 Control Box Assembly ............................... 87 025-025 Indexing Table For Fold In Half Stacker ........................89 025-027 Control Box Assembly ............................... 90 011-INST1 Material Adjustment ..............................91 Pneumatic and Wiring Diagrams ..............................92 211ES-PD1 Pneumatic Diagram ..............................93 025-PD1 Pneumatic Diagram ................................94...

- Página 6 Technical Manual & Parts Lists 025-025PD Pneumatic Diagram ..............................95 211ES-WD1 Wiring Diagram, SBUS ............................... 96 025-WD2 Wiring Diagram ................................. 97 025-WD4 Wiring Diagram ................................. 98 025-025WD2 Wiring Diagram ................................. 99 Sewing Head Details ..................................101 211-127B Sewing Head Assembly ............................... 103 211-122D Footlift Sub-Assembly ..............................

-

Página 7: Descripción

Technical Manual & Parts Lists Description Descripción The Atlanta Attachment Company’s La máquina dobladilladora de alta high speed automatic Two Needle cover velocidad de Dos agujas e hilo de stitch hemming workstation is a recubrir de la Compañía Atlanta combination unit for sleeves, pockets and Attachment es una unidad combinación... -

Página 8: Dobladilladora

Technical Manual & Parts Lists General Operating Instrucciones Generales Instructions de Operaciones y Ajustes Para la Adjustments for the Dobladilladora 2211ES de Dos Agujas Two Needle Hemmers 2211ES... -

Página 9: Operating Instructions

Technical Manual & Parts Lists Operating Instructions Instrucciones de Operación 2211ES Dobladillador de Dos Agujas Two-Needle Hemmer 2211ES READ ALL THESE INSTRUCTIONS BEFORE ¡LEA TODAS ESTAS INSTRUCCIONES OPERATING MACHINE! ANTES DE OPERAR LA MAQUINA! Wire the power cord to 208-230 VAC, 1 phase. Conecte a una corriente de 208-230 de voltaje de Corriente Alterna, de 1 fase. -

Página 10: Control Box

AP-28-800N Conveyor Speed Control Box Instructions for 211ES Instrucciones para la 211ES Note:The row of buttons across the bottom of the Nota: Los botones a lo largo de la parte de abajo de la screen are called Standard buttons. They will pantalla son los botones standard. -

Página 11: 211Es Main Screen

Technical Manual & Parts Lists 211ES Main Screen: Primera Página de la Pantalla 1. Leading Chop: This setting allows the user to 1. Corte delantero: Controla el tiempo desde que el control the amount of time from the sew eye... -

Página 12: Advanced Settings 1

1. Leading Edge Chain Cut: Same as Leading Chop 1. Cortacadeneta delantero: Igual que Corte on 211ES Main Screen.1-9 Delantero en la Página principal 1-9. 2. Foot Down Delay: Time from the sew eye seeing the 2. Retardo de bajar el prensatelas: Tiempo desde que el leading edge of the sleeve till the presser foot drops. -

Página 13: Advanced Settings 2

Technical Manual & Parts Lists 6. Chop On Time: Time the knife stays in the down 6. Tiempo activado del cortacadeneta: Tiempo que la position. Too small prevents the knife from cortadora se queda abajo. Muy poco hace que cutting reliably, too large causes the leading edge no corte bien, demasiado hace que el material se chain to wad up in front of the knife. -

Página 14: Operator Screen

Technical Manual & Parts Lists Operator Screen: Página Del Operador 1. Contrast: This setting adjusts the contrast of the 1. Contraste: Ajusta el contraste para facilitar la screen for easier viewing. The higher number the lectura. Entre más grande el número más clara se lighter the screens. - Página 15 Technical Manual & Parts Lists 4. Low air pressure detected. 4. Error, poca presión de aire. Possible Solutions: Soluciones posibles. A. Air shutoff valve is closed. A. El registro principal está cerrado. B. Air line is disconnected from machine. B. Suministro de aire desconectado. C.

- Página 16 Technical Manual & Parts Lists D. Possible defective sew eye. D. Sensor dañado. 11. Stacker eye has been covered too long. 11. Detector de bloqueo sensor del apilador. Relative Sensor activado demasiado. setting: Stacker Eye Timeout. Causas posibles. Possible Causes: A.

-

Página 17: Thread Break Detectors

Technical Manual & Parts Lists Thread Break Detectors Detectores de Rotura del Hilo A. Adjustment and function of looper thread A. Ajuste y función del detector de hilo roto del break detector. engazador. This type of thread detector monitors the Este tipo de monitor detecta el movimiento consistent movement of thread at a 5 degree constante del hilo en un ángulo de 5 grados... -

Página 18: Adjustments To The Material Edge Trimming Guide System

Technical Manual & Parts Lists Adjustments to the Material Ajustes a la Guía de la Edge Trimming Guide System Recortadora de Borde The Material Guide Roller Should Be Adjusted El Rodillo Guía de Material Debe Ajustarse En In three Dimensions Tres Dimensiones 1. -

Página 19: Adjustment To The Thread Chain Puller And Speed Control

Technical Manual & Parts Lists Note: This adjustment will have to be repeated every Nota: Este ajuste tendrá que repetirse cada vez que a time the material trimming knife is adjusted for the la cortadora se le cambia la cantidad de material a amount of trim off. -

Página 20: Height Adjustment

Technical Manual & Parts Lists 2. There are two adjustments that can be made to the 2. Hay dos ajustes que pueden hacerse al tirador de chain puller: height and levelness. la cadena: la altura y el nivelado. Height Adjustment Ajuste de la Altura In adjusting the height of the puller, set the puller so Ajuste la altura del tirador de forma que haya 1/2"... -

Página 21: Troubleshooting

Technical Manual & Parts Lists Troubleshooting Problemas y Soluciones 1. Chain cutter knife not cutting. 1. El cortacadeneta no corta. A. Manually activate solenoid valve and check A. Active manualmente la válvula y chequee la operation of air cylinder. operación del cilindro. B. - Página 22 Technical Manual & Parts Lists D. Chaining must be checked in “MANUAL D. El encadenado tiene que ser chequeado en MODE”. “MANUAL”. 6. Thread chain wraps around roller. 6. La cadeneta se envuelve alrededor del rodillo. A. Check air jets on puller bracket. A.

-

Página 23: Sewing Head Maintenance

Technical Manual & Parts Lists Sewing Head Maintenance Mantenimiento Del Cabezal 1. Oil Level 1. Nivel del Aceite Always keep enough oil in the Siempre mantenga suficiente machine so that the oil level is aceite en la máquina para que el between two lines H and L of oil nivel del aceite esté... - Página 24 Technical Manual & Parts Lists 5. Checking and Replacing Oil 5. Chequeo y Remplazo del Filter Filtro de Aceite If oil filter (item 4) is clogged, Si el filtro de aceite (artículo 4) está normal lubrication cannot be kept. obstruido, no puede haber una Check and clean it every 6 months lubricación normal.

-

Página 25: Suggested Sewing Guidelines

Technical Manual & Parts Lists Suggested Sewing Guidelines Ajustes Para Coser Con La For Pegasus W664 Pegasus W664 1. Needle Height Adjustment 1. Ajuste de la Altura de la Aguja The standard setting is as shown La posición normal es como está in Table 1. - Página 26 Technical Manual & Parts Lists 2. Setting Position of Looper 2. Ajuste de la Posicion del Engazador A. Adjusting distance (a) A. Ajuste de la distancia (a) Set the distance (a) correctly Fije la distancia (a) correctamente de according to the needle gauge as acuerdo al indicador de la aguja como shown in Table 2.

- Página 27 Technical Manual & Parts Lists C. Clearance Between Needle and Looper C. Espacio Libre Entre la Aguja y la Punta del Point. Engazador. Set the clearance between the left Fije el espacio libre entre la aguja needle and the looper point to .05 - izquierda y la punta del Engazador a .05 .1mm when the looper point is behind -.1 mm cuando la punta del Engazador...

- Página 28 Technical Manual & Parts Lists 4. Adjusting Needle Guard (Rear) 4. Ajuste del Salva Agujas (Posterior) A. Adjust so that the line (A) of needle A. Ajuste para que la línea (A) del guard (rear) (item 1) is at bottom of salvagujas (posterior) (artículo 1) esté...

- Página 29 Technical Manual & Parts Lists...

- Página 30 Technical Manual & Parts Lists 6. Adjusting Needle Thread Take- 6. Ajuste del Tira-Hilos de la Aguja (Algodón/Hilado Poli) (Cotton/Spun Poly) En la posición normal, el filo de parte In the standard setting, the top edge de arriba del soporte “6" tiene que estar of bracket “6"...

- Página 31 Technical Manual & Parts Lists 9. Adjusting Looper Thread Take- 9. Ajuste del Hilo Halado por el Engazador (Algodón/Hilado Poli) (Cotton/Spun Poly) Para coser hilo de algodón ajuste el For sewing cotton thread adjust Engazador del tira hilos como se looper thread take-up as shown in muestra (vea Fig.

- Página 32 Technical Manual & Parts Lists Notes...

-

Página 33: Suggested Sewing Guidelines

Technical Manual & Parts Lists Suggested Sewing Guidelines Ajustes Sugeridos Para for Rimoldi Rimoldi 1. Positioning Of The Needles (Fig.1) 1. Posición De Las Agujas (Fig. 1) The machine has been tuned with RIM La máquina ha sido calibrada con needles. - Página 34 Technical Manual & Parts Lists 3. Setting The Lower Looper 3. Graduación Del Engazador Inferior (Fig. 3) (Fig. 3) Insert looper A in the looper Inserte el engazador A en su soporte holder positioning it at the top posicionandolo en la parte de arriba with calibrator 315910-0-00 con el calibrador 315910-0-00 (supplied with all the machines)

- Página 35 Technical Manual & Parts Lists B. To obtain dimension 0.05 B. Para conseguir la dimensión (Fig.6) which represents the 0.05 (Fig 6) que representa la distance between the end of distancia entre el fin del the looper and the groove of engazador y la estría de la aguja the needle during its stroke durante su golpe de derecha a...

- Página 36 Technical Manual & Parts Lists 4. Setting Needle Guard (Fig. 8) 4. Ajuste del Guarda Agujas (Fig. 8) Bring Looper point (Turning machine in direction Traiga la punta del Engazador (Voltenando la of operation) as shown in Fig. 9. By loosening máquina en la dirección de la operación) como se screws C &...

-

Página 37: Phase Sheet

Technical Manual & Parts Lists 6. Assembling Feed Dogs on Feed Dog Support 6. Montado de los Dientes de arrastre en su (Fig. 13) Soporte (Fig. 13) With screw C assemble the front feed dog A in its Con el tornillo C monte los dientes de arrastre del seating in the slot of feed dog support B. - Página 38 Technical Manual & Parts Lists Notes...

-

Página 39: Suggested Guidelines For

Technical Manual & Parts Lists Suggested Guidelines For Ajustes e Instrucciones Para Yamato VC2600 Yamato VC2600 1. Enhebrado de la Máquina 1. Threading the Machine El correcto enhebrando deber hacerse siguiendo Threading should be made correctly referring to la ilustración. Un enhebrado incorrecto puede the illustration. - Página 40 Technical Manual & Parts Lists 2. Gauge Set Installation. 2. Instalación del Juego de Agujas. Remove old gauge set, refer to machine Quite el juego de agujas viejo, refierase a las specifications for proper settings. especificaciones de la máquina para la Machine specifications should have a graduación correcta.

- Página 41 Technical Manual & Parts Lists D. Use of Looper Gauge D. Uso Del Calibrador del Engazador (looper) Put the right needle in “V” Coloque la aguja de la derecha en la groove corresponding to Marks ranura en “V” correspondiente a las (A-E) on the Gauge then apply Marcas (A-E) sobre el Calibrador the point of Looper to the...

- Página 42 Technical Manual & Parts Lists H. Position of Rear Needle Guard H. Posición del Guarda Agujas Trasero. When Needles are at their Cuando las Agujas están en su lowest position, the line (A) posición más baja, la línea (A) del of rear Needle Guard is set Guarda Agujas Posterior es with the center of needle...

- Página 43 Technical Manual & Parts Lists Note: At the time of shipment, Nota: Al despachar el equipo, the avoid movement of Looper el movimiento elusivo del has been adjusted suitably to Engazador está ajustado para the use of Needle (#65- 75). el uso de Agujas (#65- 75).

- Página 44 Technical Manual & Parts Lists *Recommended Adjustments *Ajustes Recomendados At the time of shipment of A la hora del envío de las machines, Front Needle Guard máquinas, el Guardas Aguja del has been adjusted to come Frente ha sido ajustado para llegar nearest to left Needle when cerca de a la Aguja izquierda the point of Looper passes at...

- Página 45 Technical Manual & Parts Lists B. Position of Needle Thread B. Posición de la Guía del Hilo de Guide la Aguja In case of using thread of En caso de usar hilo de Polyester Spun or the like, Poliéster Hilado o semejante, when Needle Bar is at the cuando la Barra de la Aguja lowest position, the center of...

- Página 46 Technical Manual & Parts Lists * Recommended Adjustments *Ajustes Recomendados With different thread than wool, Cuando use hilos diferente a hilo de lana, La too much thread loop created by excesiva cantidad de hilo del Engazador moving eyelets to the front may surtido por los ojetes al moverlos hacia el cause skip stitches.

- Página 47 Technical Manual & Parts Lists *Ajustes Recomendados *Recommended Adjustments Referencia: Mejores costuras se obtienen si el ajuste 2) Reference: Better seams can be obtained if the cambia según el hilo del Engazador a ser el usado como adjustment 2) changed according to the looper thread to sigue.(Fig.

-

Página 48: Preventative Maintenance Schedule

Technical Manual & Parts Lists Preventative Maintenance Plan De Mantenimiento Schedule Preventivo 1. Daily Maintenance: 1. Mantenimiento Diario: A. Check v-belt tightness. A. Revisar la tensión de la correa en ¨V" del B. Check oil level – always keep level between lines cabezal. - Página 49 Technical Manual & Parts Lists C. If machine is idle for more that a couple of 3. Mantenimiento Mensual: weeks, manually lubricate needle bar before operating. A. El cambio de aceite y del filtro del cabezal D. Remove and clean the top conveyor assembly. debe ser efectuado a intervalos de 30 días o 200 E.

-

Página 50: Part List Directions

Breve descripción de la parte para mejor identificación en el dibujo. Cuando ordene repuestos utilice el número de la parte. The Atlanta Attachment Company part number. Be sure to reference this number when ordering spares. Este es el número de la parte de la Compañía Atlanta Attachment. -

Página 51: Configuration

Technical Manual & Parts Lists Configuration The Atlanta Attachment’s Units Numbers are formed in the following manner. 4411FY6701 Configuration Machine Class Code Number AAC Unit Code Number Sewing Machine Codes PEGASUS 5.6mm IMOLDI 4.5mm RIMOLDI 6.00mm SINGER 5.6mm YAMATO 4.8mm YAMATO VC2700-156M 5.6 mm YAMATO 6.4mm... - Página 52 Technical Manual & Parts Lists...

-

Página 53: Assembly Drawings & Parts Lists

Company. In addition to any confidentiality and non-disclosure obligations that currently exist between you and Atlanta Attachment Company, your use of these materials serves as an acknowledgment of the confidential and proprietary nature of these materials and your duty not to make any unauthorized use or... -

Página 54: 2211Esy6704 Auto Hemmer Yamato 5.6Mm Ga. W/Panasonic Motor

Top Conveyor 211-062C Foot 5.6 mm Ga. Page Page 79 211-G6606C Hemming Folder 211-063C Feed Dog 5.6mm Ga. Page Page 93 211ES-PD1 Pneumatic Diagram 211-127B Sewing Head Assembly Page 103 Page Page Page 96 211ES-WD1 Wiring Diagram Pana ZZ211ES Technical Manual... -

Página 55: 2211Esy6207 Auto Hemmer Yamato 5.6Mm W/Panasonic Motor

Feed Dog 5.6mm Ga. Page Page 79 Page 103 211-G6606C Hemming Folder 211-127B Sewing Head Assembly Page Page Page 93 211ES-PD1 Pneumatic Diagram 211-141 Bundle Table Page Page 96 211ES-WD1 Wiring Diagram Pana ZZ211ES Technical Manual Page 211-2P Hemmer Head... - Página 56 Technical Manual & Parts Lists...

-

Página 57: 2211Esy6202 Auto Hemmer Yamato 5.6Mm W/Panasonic Motor

Page 77 211-151A Stacker 90847 Tension Spring Page Page 79 211-G6606C Hemming Folder 90071 Tension Retainer Page Page 93 211ES-PD1 Pneumatic Diagram Felt Washer Page Page 96 211ES-WD1 Wiring Diagram Panasonic 31111 Tension Disc Page 211-2N Hemmer Head 9835 Tension Post... - Página 58 Technical Manual & Parts Lists...

-

Página 59: 211-126C Table Assembly

Control, SBUS, AEI MM16300 Tube Clamp SSPS90032 Scr,Pn Hd Sl 8-32x1/2 211-157 Waste Tube Page 93 AP-28-800NN Control Box, Stepper AR 211ES-PD1 Pneumatic Diagram Page 96 WWL1/4 1/4 Lock Washer AR 211ES-WD1 Wiring Diagram Pana 12 WWF1/4 Flat Washer 40-112A... -

Página 60: 211-125A Table Assembly

211-125A Table Assembly AAC Drawing Number 191929C Rev 1 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION Page 55 211-124B Bottom Side Assembly AR 211ES-WD1 Wiring Diagram Pana Page 96 Page Page 0411-1903 Foot Switch WWL1/4 Lock Washer SSZS93032... -

Página 61: 211-124B Bottom Side Assembly

Pneumatic Diagram Page 211-208 Control Box Mount AAQSU-5-5 Quick Union NNJ1/2-20 1/2-20 Jam Nut SSHC10064 Scr,Hx Cp 5/16x1 211-124A Isolator Post WWF5/16 Washer, Flat Page 96 AR 211ES-WD1 Wiring Diagram Pana MM503022LB Rubber Caster Page 011-099 Clamp Bracket WWL5/16 Washer, Lock... - Página 62 Technical Manual & Parts Lists...

-

Página 63: Electronic Assembly

Tube, Adaptor FF1724 Strain Relief 211-204 Panel, Electrical 20’ FF19510 Cable, 3 Cond 211-207 Cable Package FF264-341 Terminal Block AR 211ES-LAB1 Label, Valves FF264-347 Terminal Block Page 93 AR 211ES-PD1 Pneumatic Diagram FF264-371 Terminal Block Page Page 96 AR 211ES-WD1... -

Página 64: 0411-1057 Waste Venturi Assembly

Technical Manual & Parts Lists 0411-1057 Waste Venturi Assembly AAC Drawing Number 190467B Rev 0 QTY PART # DESCRIPTION 211142 Waste Venturi AAF2304-2 Needle Valve AAF10684 Brass Fitting AAQMC-4-8 Quick Male Connect... -

Página 65: Edge Trimmer Mount Assembly

Technical Manual & Parts Lists 211-120 Edge Trimmer Mount Assembly AAC Drawing Number 191009B Rev 7 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION MMB6002 Mount, Vibration, Motor NNK1/4-20 Nut, Kep, 1/4-20 TTK32309 TorK Knob-Stub NNJ5/16-18 Nut, Jam SSSC98024 Scr,So Cp 10-32x3/8 WWFS5/16 Washer, SAE... -

Página 66: 211-G6602 Drive Train Assembly

Technical Manual & Parts Lists 211-G6602 Drive Train Assembly AAC Drawing Number 190182B Rev 5 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION 211-025 Gear Pulley 211-069 Nut Pl SSPS98032 Scr,Pan Sltd 10-32x1/2 SSHC10144 Scr,Hx Cp 5/16-18x2-1/4 WWSI10 #10 Int Lock Washer WWF5/16 Washer 011-018... -

Página 67: Transfer Drive Assembly

Technical Manual & Parts Lists 211-034 Transfer Drive Assembly AAC Drawing Number 290131B Rev 8 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION MM2X897 1/2 Pillow Blocks 211-057 Pulley, Mod SSFC90048 Scr,Fl Al Cp 8-32X3/4 211-028 Pl Top Conv Dr SSHC20048 Scr,Hx Cp 5/16-24X3/4 211-047 Gear Adaptor... - Página 68 Technical Manual & Parts Lists...

-

Página 69: 211-121A Edge Trimmer Assembly, Sbus

Technical Manual & Parts Lists 211-121A Edge Trimmer Assembly, SBUS AAC Drawing Number 192051C Rev 4 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION CC192024 Collar 255510 Clamp EEMS221005C Motor, 24VDC, 2.1A SSBC01032 Scr,But Cp 1/4-20x1/2 211-172 Cable WWFS1/4 SAE Washer CCSC41/4... - Página 70 Technical Manual & Parts Lists...

-

Página 71: Lower Conveyor Assembly

Technical Manual & Parts Lists 211-128 Lower Conveyor Assembly AAC Drawing Number 190012D Rev 8 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION K-102-21 Threaded Rod 2/12 211-123 Belt Idler, Narrow Page 66 211-101 Belt, Urethane 010-049 Roller, Aluminum 211-004A Mount, Tensioner 24.1... -

Página 72: Narrow Belt Idler Assembly

Technical Manual & Parts Lists 211-123 Narrow Belt Idler Assembly AAC Drawing Number 190701B Rev 3 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION 010-047D Yoke, Roller 11 010-047B Shaft 211-109C Plate, Stripper UUFF609-01 Bearing, Bronze, Flng 010-047C Roller WWFS10 Washer, SAE #10... -

Página 73: 0411-1300 Waste Container Assembly

Technical Manual & Parts Lists 0411-1300 Waste Container Assembly AAC Drawing Number 191225C Rev 8 NO. QTY PART# DESCRIPTION NO. QTY PART# DESCRIPTION MMTC32GTAN Container, Waste 26282 Filter Holder MM5415K16 Hose Clamp 26285A Filter, Waste System MM16300 Tube Clamp SSPS90024 Scr,Pn Hd Sl 8-32x3/8 MMRPL150 Plain Elbow... - Página 74 Technical Manual & Parts Lists...

-

Página 75: Top Conveyor, 2 Belt

Technical Manual & Parts Lists 211-134 Top Conveyor, 2 Belt AAC Drawing Number 191307C Rev 12 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION Page 71 211-171 Top Conveyor, Generic WW25DW Washer Plate Page 211-139 Bracket, Rear WWL8 Washer, Lock 011-046A Cover, Top Conveyor... - Página 76 Technical Manual & Parts Lists...

-

Página 77: Top Conveyor Internal Components

Technical Manual & Parts Lists 211-171 Top Conveyor Internal Components AAC Drawing Number 191359C Rev 5 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION 011-050 BracKet, Adjustment 211-003 Plate, Right Side NNH10-32 Nut, Hex 211-049 SprocKet, Idler, 10T 011-052 Top Conv Mount 011-037... - Página 78 Technical Manual & Parts Lists...

-

Página 79: 211-134B Top Conveyor, 2 Belts

Technical Manual & Parts Lists 211-134B Top Conveyor, 2 Belts AAC Drawing Number 191650C Rev 3 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION Page 74 311-061 Keel Assembly SSSC98032 Scr,So Cp 10-32x1/2 Page 011032B Spacer RRLC024C10 Spring Page 75 311-002 Main Drive... -

Página 80: Keel Assembly, ¾ Wide Cuff

Technical Manual & Parts Lists 311-061 Keel Assembly, ¾ Wide Cuff AAC Drawing Number 190321B Rev 3 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION 211-082 Latch, Tuck Fold NNH10-32 Hex Nut, 10-32 211-080 Tuck Fold Blade WWFS6 Washer 211-079 Mount, Tuck Fold... -

Página 81: Top Conveyor, Main Drive

Technical Manual & Parts Lists 311-002 Top Conveyor, Main Drive AAC Drawing Number 190255B Rev 7 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION IID016X112 Dowel Pin 211-075 Belt Guard BBTT601 Thrust Bearing 211-077 Tensioner 211-014 Pulley, Top Conveyor 211-076 Shaft Top Drive 211-013... - Página 82 Technical Manual & Parts Lists...

-

Página 83: 211-151A Stacker, Pick And Stack

Technical Manual & Parts Lists 211-151A Stacker, Pick and Stack AAC Drawing Number 191055B Rev 11 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION AAQME-5-10 Quick Male Elbow SSSCM5X15 Scr,So Cp M5-0.8x14 AAC8SH-.5A Cylinder, Air SSPS98024 Scr, Pn Sl 10-32x3/8 AACR25813 Cylinder, Air SSHC01112... -

Página 84: 016-014A Material Clamp Assembly

Technical Manual & Parts Lists 016-014A Material Clamp Assembly AAC Drawing Number 190681C Rev 13 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION IID016X192 Dowel Pin, 1/4 X 3 " WWSI8 Washer, Int Teeth, #8 NNK10-32 Nut, Kep 10-32 016-015 Bracket, Clamp Assy. -

Página 85: 211-G6606C Hemming Folder Assembly

Technical Manual & Parts Lists 211-G6606C Hemming Folder Assembly AAC Drawing Number 190185B Rev 6 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION NNH10-24 Hex Nut 011-012A Tongue, Folder SSPS95024 Scr,Pn Sl 10-24x38 011-013A Edge Guide, Right TTCL1BPPK1 Knob, 10-24 011-060 Support, Lower Folder WWFS10... -

Página 86: Indexing Table

Technical Manual & Parts Lists 211-162 Indexing Table AAC Drawing Number 191010B Rev 4 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION 211-162-1 Table Top Weldment 20’ AATP5/32 5/32 Air Line 211-162B8 Leg Weldment NNH1/2-13 Hex Nut 211-162B7 Stand Weldment SSSC01096 Scr,So Cp 1/4-20x1-1/2... -

Página 87: Fold In Half Stackerassembly

Technical Manual & Parts Lists 311-006 Fold In Half StackerAssembly AAC Drawing Number 190887C Rev 15 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION BBNTA613 Thrust Bearing WWF1/4 Washer BBTRA613 Thrust Washer SSBC98032 Scr,But Cp 10-32x1/2 MMS064 Hook SSSC98096 Scr,So Cp 10-32x1 1/2 RR9640K25 Spring, Ext. - Página 88 Technical Manual & Parts Lists...

-

Página 89: 311-006B Fold In Half Assembly

Technical Manual & Parts Lists 311-006B Fold In Half Assembly AAC Drawing Number 191618C Rev 6 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION 14 " ZTH3/8 Heat Shrink NNJ5/16-18 Jam Nut BBTRA613 Thrust Washer 025-009 Axle, Main Drive 1.5’... - Página 90 Technical Manual & Parts Lists...

-

Página 91: 311-006A Fold In Half Stacker Sub-Assembly

Technical Manual & Parts Lists 311-006A Fold In Half Stacker Sub-Assembly AAC Drawing Number 190888C Rev 12 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION SSPS90024 Scr,Pn Hd Sl 8-32x3/8 17 WWK5/16 Lock Washer AA198RA508 Flow Control 017-018 Lever, Clutch Roller AAC6DP-.5B Cyl, Air, 1.06 B, .5 S... - Página 92 Technical Manual & Parts Lists...

-

Página 93: Control Box Assembly

Technical Manual & Parts Lists 025-001 Control Box Assembly AAC Drawing Number 190784C Rev 9 QTY PART # DESCRIPTION QTY PART # DESCRIPTION AAE45A24D Air Solenoid Valve W1061-1 Plate, On/Off FF264-341 Dual Wago Terminal AAVF51FM1B Air Electric Switch FF264-311 Single Wago Terminal 025-022 Nut Plate FF264-371... - Página 94 Technical Manual & Parts Lists...

-

Página 95: Indexing Table For Fold In Half Stacker

Technical Manual & Parts Lists 025-025 Indexing Table For Fold In Half Stacker AAC Drawing Number 191074C Rev 5 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION AA198RA408 Flow Control 025-025WD2 Wiring Diagram Page 99 AAC6DP-18 Air Cylinder 025-026 Table Top Page 90... -

Página 96: Control Box Assembly

Technical Manual & Parts Lists 025-027 Control Box Assembly AAC Drawing Number 190367B Rev 4 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION AAQBU-5-5 Bulkhead Union 025-025PD Pneumatic Diagram Page 95 Page AAQPR-8-5 Reducer 4000-08 Mounting Supp AAE520301 Air Switch 4000-07 Mount... -

Página 97: 011-Inst1 Material Adjustment

Technical Manual & Parts Lists 011-INST1 Material Adjustment 290035C... -

Página 98: Pneumatic And Wiring Diagrams

Technical Manual & Parts Lists Pneumatic and Wiring Diagrams... -

Página 99: 211Es-Pd1 Pneumatic Diagram

Technical Manual & Parts Lists 211ES-PD1 Pneumatic Diagram 125456C... -

Página 100: 025-Pd1 Pneumatic Diagram

Technical Manual & Parts Lists 025-PD1 Pneumatic Diagram 125252A... -

Página 101: 025-025Pd Pneumatic Diagram

Technical Manual & Parts Lists 025-025PD Pneumatic Diagram 125262A... -

Página 102: 211Es-Wd1 Wiring Diagram, Sbus

Technical Manual & Parts Lists 211ES-WD1 Wiring Diagram, SBUS 125446C... -

Página 103: 025-Wd2 Wiring Diagram

Technical Manual & Parts Lists 025-WD2 Wiring Diagram 125095A... -

Página 104: 025-Wd4 Wiring Diagram

Technical Manual & Parts Lists 025-WD4 Wiring Diagram 125430C... -

Página 105: 025-025Wd2 Wiring Diagram

Technical Manual & Parts Lists 025-025WD2 Wiring Diagram 125911B... - Página 106 Technical Manual & Parts Lists...

-

Página 107: Sewing Head Details

Technical Manual & Parts Lists Sewing Head Details 2211ES Two Needle Hemmer Gauge Parts 211P48 Gauge Set For Pegasus 4.8mm 257016B48M Needle Plate, 3N, Pegasus 4.8mm 257301A48M Modified Foot , Pegasus 4.8mm 25724216FM Feed Dog Modified, Pegasus 4.8mm 211P56 Gauge Set For Pegasus 5.6mm 257018B56M Needle Plate, Pegasus 5.6mm 257301A56M... - Página 108 Technical Manual & Parts Lists...

-

Página 109: 211-127B Sewing Head Assembly

Technical Manual & Parts Lists 211-127B Sewing Head Assembly AAC Drawing Number 192063C Rev 6 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION SSM7145 Sewing Machine Screw 211-153 Eye Mount, Front SSSS98008 Scr,So St 10-32x1/8 3101760 Thread Kit Page 109 SSHC10064 Scr,Hx Cp 5/16-18x1.0... -

Página 110: 211-122D Footlift Sub-Assembly

Technical Manual & Parts Lists 211-122D Footlift Sub-Assembly AAC Drawing Number 192003B Rev 0 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION NNJ1/4-28 Jam Nut NNW3/8-24 Wing Nut 11200 Bumper SSSC35192M Scr, Post 3/8-24x3.0 AAQME-5-8 Quick Male Elbow 211-161B Footlift Bracket AAC7D-1... -

Página 111: 311-3000C Chain Puller Assembly

Technical Manual & Parts Lists 311-3000C Chain Puller Assembly AAC Drawing Number 191023B Rev 6 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION AAQME-5-10 Quick Male Elbow 1975-213 Air Cylinder BBAW-3Z Rod End 311-3004A Pulley, 16 Tooth 311-3010 Chain Puller Roller 311-3001C Puller Arm... -

Página 112: Ap-22E-105 Drive Motor Assembly

Technical Manual & Parts Lists AP-22E-105 Drive Motor Assembly AAC Drawing Number 190170B Rev 3 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION AP-22E-103 Step Motor AP-22E-101 Bracket. Motor Adaptor MML050 Spider SSSC90048 Scr, Socket Cap, 8-32x3/4 MML050-250 Coupling Body NNH8-32 #8 Nut MML050-375 Coupling Body... -

Página 113: 211-129A Chain Trimmer

Technical Manual & Parts Lists 211-129A Chain Trimmer AAC Drawing Number 192064C Rev 0 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION 311-2002A Pressure Plate SSFC80024 Scr,Fl Al 6-32x3/8 311-2009F Plate, Mount WWB6S Washer, Brass 311-2001A Venturi Pl. Trimmer 311-20016 Washer Plate SSSC70016 Scr,So Cp 4-40x1/4 311-2017... -

Página 114: 311-2017 Thread Trim Assembly

Technical Manual & Parts Lists 311-2017 Thread Trim Assembly AAC Drawing Number 191337C Rev 13 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION AAQMC-5-10 Quick Male Conn 311-2005 Cutter Blade, Mov CCCL3F Collar, Clamp 3/16 311-2006 Blade, Stationary CCSC33/16 Collar, Set 3/16 311-2007... -

Página 115: 3101760 Thread Handling Assembly

Technical Manual & Parts Lists 3101760 Thread Handling Assembly AAC Drawing Number 290600C Rev 8 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION 3101760A Bracket, Main SSPS90016 Scr,Pn Sl 8-32x1/4 3101760B Bracket, Tension 1975-213 Air Cylinder 0093863 Tension Cap NNH10-32 Hex Nut 0090847... -

Página 116: 311-2018 Thread Trimmer Adjustment Instructions

Technical Manual & Parts Lists 311-2018 Thread Trimmer Adjustment Instructions 261321C... - Página 117 Technical Manual & Parts Lists...

-

Página 118: Terms And Conditions

Atlanta Attachment Company (AAC) Statement of Warranty Manufactured Products Atlanta Attachment Company warrants manufactured products to be free from defects in material and workmanship for a period of eight hundred (800) hours of operation or one hundred (100) days whichever comes first. Atlanta Attachment Company warrants all electrical components of the Serial Bus System to be free from defects in material or workmanship for a period of thirty six (36) months. -

Página 119: Declaración De Garantia

Productos Manufacturados Atlanta Attachment Company garantiza que los productos de fabricación son libres de defectos de mate-rial y de mano de obra durante un periodo de ochocientos (800) horas de operación o cien (100) días cual llegue primero. Atlanta Attachment Company garantiza que todos los componentes del Serial bus son libres de defectos de material y de mano de obra durante un periodo de treinta y seis (36) meses. - Página 120 Atlanta Attachment Company 362 Industrial Park Drive Lawrenceville, GA 30046 770-963-7369 Printed in the USA www.atlatt.com...