Publicidad

Enlaces rápidos

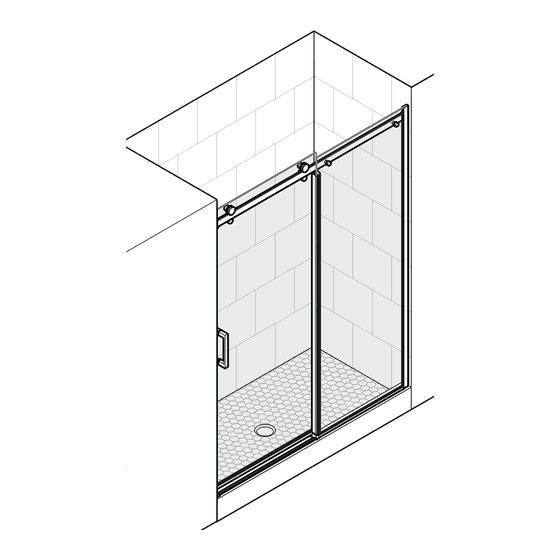

COMMIX Exposed Roller

Shower Door

5/16" glass (8mm)

De rodillo expuesto COMMIX

Puerta de Ducha

Vidrio de 5/16" (8 mm)

INSTALLATION GUIDE / GUÍA DE INSTALACIÓN

CAUTION: To reduce the risk of breakage, keep corner protectors on glass while installing.

PRECAUCIÓN: Durante la instalación, coloque vidrio o protectores de esquinas para reducir el riesgo de romperse.

Keep corner protectors for use in case future adjustments are needed.

Conserve los protectores de esquina para usarlos en caso de que sean necesarios futuros ajustes.

Consult your local plumbing codes prior to installation.

Consulte los códigos de fontanería locales antes de la instalación.

Recommended Clearance Heights for Installation:

78 inches (198 cm)

Recommended Width for Installation:

48-inch enclosure:

46 - 48 inches (116.8 - 121.9 cm)

60-inch enclosure:

54-3/8 - 60 inches (138.1- 152.4 cm)

48-inch Enclosure

Recinto de 48 pulg.

1

Altura libre recomendada para la instalación:

78 pulgadas (198 cm)

Ancho recomendado para la instalación:

Recinto de 48 pulg.:

46 a 48 pulg. (116.8 a 121.9 cm)

Recinto de 60 pulg.:

54-3/8 a 60 pulg. (131.1 a 152.4 cm)

60-inch Enclosure

Recinto de 60 pulg

December 2019

Publicidad

Resumen de contenidos para Delta COMMIX

- Página 1 COMMIX Exposed Roller Shower Door 5/16" glass (8mm) De rodillo expuesto COMMIX Puerta de Ducha Vidrio de 5/16" (8 mm) INSTALLATION GUIDE / GUÍA DE INSTALACIÓN CAUTION: To reduce the risk of breakage, keep corner protectors on glass while installing.

- Página 2 Guantes antirresbalantes Tijeras para chapa fina y resistentes al corte IMPORTANT: To install your Delta shower door unit, IMPORTANTE: Para instalar la unidad de puerta de ducha you must: (1) completely read all instructions, warnings, Delta, debe: (1) leer completamente todas las instrucciones, cautions, and care and maintenance information;...

-

Página 3: Before You Start

If you see any wear or damage to your glass panels call Delta Customer Care to receive a replacement panel at 1-800-964-4850. CAUTION... -

Página 4: Antes De Comenzar

Delta para recibir un panel de reemplazo a 1-800-964-4850. PRECAUCIÓN La instalación de los paneles de vidrio con mellas, astillas o rayones puede provocar lesiones, daños a la propiedad... -

Página 5: Carton Parts Identification / Identificación De Las Partes

CARTON PARTS IDENTIFICATION / IDENTIFICACIÓN DE LAS PARTES See following pages for detailed component diagrams / Consulte en las páginas siguientes los diagramas detallados de los componentes Part Description Qty. Pieza Descripción Cant. Sliding Door Panel Panel de puerta corrediza Panel fijo Fixed Panel Top Track Assembly... -

Página 6: Door Assembly / Montaje De La Puerta

DOOR ASSEMBLY / MONTAJE DE LA PUERTA CAUTION: To reduce the risk of breakage, which may result in personal injury, property damage or product failure, DO NOT set glass panels on a hard surface or on their edge. PRECAUCIÓN: Para reducir el riesgo de rotura, que puede provocar lesiones, dañ... - Página 7 HARDWARE / ERRAJE M6 x 30 FH Screw Tornillo FH M6 x 30 Fixed Glass Support Assembly Ensamble de apoyo para el vidrio fijo Roller Assembly Conjunto de rodillo Limit Stop Bracket Assembly Conjunto de soporte de tope Limit Stop Assembly Screw Tornillo limitador de conjunto Wall Bracket Assembly Ensamble de soporte de pared...

- Página 8 HARDWARE / ERRAJE Top Track Assembly Ensamble de carril superior Limit Stop Screw Tornillo limitador Allen Wrenches Included Llaves Allen Incluidas (2.5mm and 4mm) Spare Water Diverter Desviador de agua de repuesto Handle Assembly Adjustment Wrench Included Conjunto de asa Llave de ajuste incluida...

-

Página 9: Importante

B = Ancho inferior del recinto NOTE: Door height is 76" (193 cm). Recommended Clearance Height for installation is 78" (198 cm.) This Commix Exposed Roller Shower Door can be installed to open from either side of your enclosure depending on showerhead/control valve location. - Página 10 Locating Mounting Stud Position IMPORTANT: Using a stud finder, ensure that the wall on the door side of the enclosure has a stud in the location shown. A stud in this location must be identified to support the top track in order to proceed with the installation.

- Página 11 Using a pencil or masking tape, mark the calculated distance "B" from the front of the sill on the opposite side of the enclosure as shown in figure 5. This will indicate the location of your fixed panel. Con un lápiz o cinta de enmascarar, marque la distancia calculada “B”...

- Página 12 Using a pencil, mark location of all four screw holes for fixed panel wall jamb (D). Con un lápiz, marque la ubicación de los cuatro orificios de los tornillos para la jamba de pared del panel fijo (D). CAUTION To avoid risk of injury or product damage, make sure that you drill into studs.

- Página 13 Insert anchors (U) in each hole location. The anchors should fit securely into the holes. If needed, a rubber mallet can be used to insert anchors. To reduce risk of property damage, the use of metal hammers is not recommended. If needed, use drill to slightly enlarge the opening of the hole.

- Página 14 Inspeccione todos los bordes y esquinas de los paneles de vidrio para detectar mellas, astillas o rayones que podrían haberse producido durante su traslado. Si ve desgaste o daños en los paneles de vidrio, llame a Delta Customer Care por el 1-800-964-4850 para recibir un panel de reemplazo. CAUTION CAUTION Risk of injury or product damage.

- Página 15 **Step For a 48" Shower Door System ONLY** Using a pencil or other marking tool (such as masking tape), mark 21" (53.6 cm) from one end of the U-channel (E). **Paso únicamente para la puerta de ducha de 48"** Con un lápiz u otra herramienta para marcar (como una cinta de enmascarar), marque 21"...

- Página 16 With fixed door panel (B) laid flat, carefully remove two corner protectors from bottom of glass panel. This will be the edge away from mounting holes and glass label. Install the U-channel (E) to the bottom edge of fixed door panel (B).

- Página 17 Remove inside corner protector from top of fixed door panel. Carefully, and with assistance from another capable person, position the fixed glass panel (B) into the fixed panel wall jamb (D). Ensure that glass notice label is facing into the shower. Retire el protector de esquina interior de la parte superior del panel fijo de la puerta.

- Página 18 Check that the measurement from front of sill to fixed door panel is the same at the wall and the center of enclosure. Clean off any excess silicone. Compruebe que la medición desde el frente del umbral hasta el panel fijo de la puerta sea la misma en la pared y en el centro del recinto.

- Página 19 If Installing into a 48" enclosure, the water diverter seal (P) will need to be cut to 25-5/16" (64.3cm). Using a pencil or other marking tool (such as masking tape), mark the above measurement on the water diverter seal (P). Double check the measurement before cutting.

- Página 20 IMPORTANT: Place multiple layers of cardboard inside the base of the shower enclosure pan to support the sliding door panel (A). Carefully, and with assistance from another capable person, place sliding door panel into enclosure against rear wall. NOTE: Door handle holes should be facing away from the fixed panel (as shown in figure 23).

- Página 21 Top Track Using a pencil or another marking tool (such as masking Carril superior tape), mark distance “D” on the top track (C) from the edge of the top track as shown in figure 25. IMPORTANT: The top track (C) will have a label which says “Cut This End Only”.

- Página 22 Check to ensure that end cap (G) is installed to the end of top track (C) which will be towards the fixed panel. This will be the end which was not cut in step 26. Asegúrese de que se instala la tapa protectora (G) en el extremo del carril superior (C) que queda hacia el panel fijo.

- Página 23 Attach the top track (C) to the inside of the fixed glass panel (B) with the fixed glass support (F) as shown in figure 29. Use provided Allen wrench to hand tighten. IMPORTANT: Ensure all washers and bushings are installed as shown. Repeat for remaining fixed glass support (F).

- Página 24 Make sure that outline traced in step 30 aligns with the top track (C). Confirme que el trazo descrito en el paso 30 queda alineado con el carril superior (C). Loosen and remove the inner fixed panel support (F). This will be the assembly closest to the exposed glass edge (shown in figure 32).

- Página 25 Carefully lower the top track into vertical position (shown in figure 33), while installing the mounting bracket in the following steps. Cuidadosamente, baje el carril superior hasta que quede en posición vertical (mostrada en la figura 33), mientras se instala el soporte de montaje en los siguientes pasos. CAUTION Risk of injury or product damage.

- Página 26 Center mounting bracket (HH) within mark made in step 30. IMPORTANT: Bracket must be located on a stud. Mark the center hole location. Centre el soporte del montaje (HH) dentro de la marca realizada en el paso 30. IMPORTANT: El soporte debe ubicarse sobre un montante.

- Página 27 Insert anchor (U) in hole location. The anchor should fit securely into the hole. If needed, a rubber mallet can be used to insert anchor. To reduce risk of property damage, metal hammers are not recommended to be used. If needed, use drill to slightly enlarge the opening of the hole.

- Página 28 Slide bracket collar (GG) onto end of top track (C) and carefully rotate top track back to horizontal (90 degrees). IMPORTANT: Ensure that the two pointed set screws (II) will be closest to the wall when reinstalled. Deslice el collarín de soporte (GG) por el extremo del carril superior (C) y gire cuidadosamente el carril superior de regreso a la posición horizontal (90°).

- Página 29 Slide bracket collar (GG) outward (toward wall) over mounting bracket (HH). Tighten all four Allen screws by hand until secure. IMPORTANT: The pointed Allen screws MUST be oriented closest to the wall when bracket collar (GG) is reinstalled. Deslice el collarín de soporte (GG) hacia afuera (hacia la pared) sobre el soporte de montaje (HH).

- Página 30 CAUTION To avoid risk of injury or product damage, make sure that you drill into studs. PRECAUCIÓN Drill a 1/8" pilot hole at location marked for center guide. Next, redrill a 7/32" hole at location to accept Para evitar el riesgo de lesiones o daños al producto, anchor (U).

- Página 31 *Inside Enclosure* *Dentro del recinto* Use silicone caulk to seal the inner edge of the fixed panel (B). Use masilla de silicona para sellar el borde interno del panel fijo (B). Attach center guide (L) using screw (X). Use drill to start screw (X) into anchor (U).

-

Página 32: Instalación De La Barrera

Dam Strip Installation Using a measuring tape, measure distance between the center guide and the door side wall. This will be measurement “E”, the length of the bottom track. Instalación de la barrera Usando una cinta métrica, mida la distancia entre la guía central y la pared del lado de la puerta. - Página 33 IMPORTANT: Double check the measurement before cutting. Using a miter box, cut the bottom dam strip (N) with a fine-toothed (32 TPI) hack saw. If needed, use a metal file to smooth rough edges. Clean CAUTION up metal shavings. IMPORTANT: DO NOT stand on or use a vice to hold To avoid risk of injury or product damage, make sure that dam strip while cutting.

- Página 34 Slide the dam strip (N) into the center guide (L). There will be a small gap between the end of the dam strip (N) and the side wall which will be covered by the dam strip support (O). NOTE: Ensure that dam strip is parallel to front of sill. Deslice la barrera (N) hacia la guía central (L).

- Página 35 CAUTION To avoid risk of injury or product damage, make sure that you drill into studs. After removing dam strip support, drill a 1/8" pilot hole PRECAUCIÓN at the location marked in the previous step. Next, re-drill a 7/32" hole to accept the anchor (U). Para evitar el riesgo de lesiones o daños al producto, asegúrese de perforar en los montantes.

- Página 36 Reinstall the dam strip support (O). Use drill to start M4 x 30 FH screw (X) into anchor. Apply silicone sealant under and around dam strip support (O). Next, use a screwdriver to hand tighten until secure. Install screw cap (W) into screw hole, a dot of silicone can be applied over the screw head to secure.

- Página 37 Installing the Sliding Door Panel Assembly (I) Using provided adjustment wrench, disassemble roller Conjunto (I) assembly (I) as shown in figure 57. Repeat for the remaining roller assembly. Instalación del panel de puerta corrediza Utilice la llave de ajuste suministrada para ajustar, desmonte el conjunto del rodillo (I) como se muestra en la figura 57.

- Página 38 From inside of enclosure, carefully, and with assistance from another capable person, hang sliding door panel (A) and roller assemblies (I) onto top track assembly (C). Ensure bottom of door panel (A) is properly engaged in channel of center guide. Desde dentro del recinto, cuidadosamente, y con ayuda de otra persona capaz, cuelgue el panel de puerta corrediza (A) y los conjuntos de rodillo (I) sobre el...

-

Página 39: Ajuste Del Tope

*Inside Enclosure* *Dentro del recinto* From inside enclosure, install limit stop bracket assembly (K) to inside of sliding door panel (A) as shown in figure 61. Use Phillips screwdriver to hand tighten until secure. Desde dentro del recinto, instale el conjunto de soporte de tope (K) en el interior del panel de puerta corrediza (A) como se muestra en la figura 61. - Página 40 Limit Stop Adjustment (continued) Re-tighten limit adjustment screw by hand until fully secure and install limit stop cover cap (VV). Ajuste del tope (continuación) Vuelva a apretar a mano el tornillo de ajuste limitador hasta que quede completamente firme e instale la cubierta del tope (VV).

- Página 41 Roller Assembly Adjustment (continued) Using larger hex slot on provided adjustment wrench, tighten nut (NN) until fully secure. Install roller back cover (OO). Repeat steps 64-65 for remaining roller assembly as *Inside Enclosure* needed. *Dentro del recinto* Ajuste del conjunto de rodillo (continuación) Usando la ranura hexagonal más grande en la llave de ajuste suministrada, apriete la tuerca (NN) hasta que quede completamente firme.

- Página 42 Install the anti-jump assembly (J) into the remaining holes in the sliding door panel (A) below the top track as shown in figure 67. Use provided adjustment wrench to hand tighten until secure. Repeat for remaining anti-jump assembly (J). Instale el ensamble estabilizador (J) en los orificios restantes en el panel de puerta corrediza (A) debajo del carril superior, como se muestra en la figura 67.

- Página 43 Anti-Jump Adjustment (continued) Using larger hex slot on provided adjustment wrench, tighten nut (NN). Re-install cap (RR) on front of anti-jump assembly. Repeat steps 68-69 for remaining anti-jump assembly (J). Ajuste del estabilizador (continuación) Usando la ranura hexagonal más grande en la llave de ajuste suministrada, apriete la tuerca (NN).

- Página 44 Open sliding door panel. Align the inner face of magnetic seal wall jamb (Q) with the mark made in previous step. Ensure the open end of the seal wall jamb (Q) mates with the wall as shown in figure 71. Tape magnetic seal wall jamb in place.

- Página 45 1/8" Remove magnetic seal wall jamb and drill a 1/8" pilot hole at each location marked, if not already done in previous step. Next, redrill a 7/32" hole at each location to accept the anchor (U). Retire la jamba de pared de junta magnética y perfore un orificio guía de 1/8"...

- Página 46 Reposition magnetic seal wall jamb (Q). Use drill to start the M4 x 35 screws (T) into the anchors. Next, use a screwdriver to hand tighten until secure. Vuelva a colocar la jamba de pared de junta magnética (Q). Utilice la broca para abrir camino a los tornillos M4 x 35 (T) en los anclajes.

- Página 47 Test the closure of the door to check that the seals are evenly aligned with no gaps. If needed, the sliding door panel can be adjusted using offsets in the roller (see figures 64-65). If gaps still persist, see troubleshooting section at end of instruction booklet.

- Página 48 Install remaining blade seal (S) to the inside edge of the fixed panel (B) as shown in figure 79. For best water retention, ensure that the bottom edge of blade seal (S) is in contact with the top of center guide (L/M).

- Página 49 Install handle pull (WW), and two handle bushing washers (ZZ) on outer side of sliding door panel (A). Install two handle bushing washers (ZZ), inner handle knob (XX) and bottom handle plate (YY) on inside of sliding door panel (A). Turn inner handle knob and plate to secure.

- Página 50 Optional: Shower environments can have different types of shower head fixtures and orientations. If needed for additional water retention, an additional spare water diverter with adhesive (Y) has been provided which can be cut and installed (if needed) as shown. Opcional: Los ambientes de ducha pueden tener diferentes tipos y orientaciones de accesorios de cabezales de ducha.

- Página 51 TROUBLESHOOTING Symptom: Alignment Recommended Action 1. Magnetic Seals not fully aligned - gaps are present a. Adjust height of rollers (see steps 64-65) independently to close gaps at top or bottom of seals. between the magnetic seals. b. With sliding door closed, use a thin plastic shim to push the magnetic seal of the door towards the magnetic seal of the wall jamb.

-

Página 52: Solución De Problemas

SOLUCIÓN DE PROBLEMAS Síntoma: Alineación Síntoma: Alineación 1. Las juntas magnéticas no están completamente a. Ajuste la altura de los rodillos (consulte los pasos 64-65) independientemente para cerrar los espacios en la parte alineadas, quedan espacios entre las juntas superior o inferior de las juntas. magnéticas.